[su_image_carousel source=”media: 50990,50991″]

Introduction

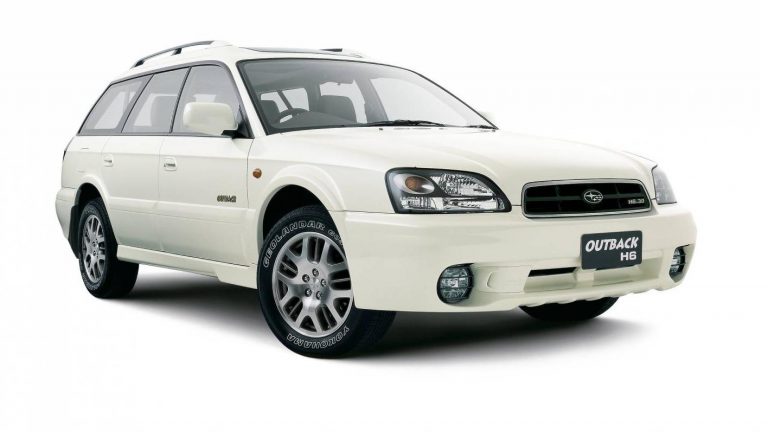

Subaru’s EZ30D was a 3.0-litre horizontally-opposed (or ‘boxer’) six-cylinder petrol engine. For Australia, the EZ30D engine was solely available on the Subaru BH Outback from 2000-03. Key features of the EZ30D engine included its:

- Open-deck, die-cast aluminium block;

- Aluminium alloy cylinder head;

- Double overhead camshafts actuating four valves per cylinder via shim-over-bucket lifters;

- Variable induction system;

- Two-stage exhaust;

- Compression ratio of 10.7:1;

- Coil-on-plug ignition; and,

- Maximum engine speed of 6500 rpm.

This article considers the EZ30D engine as it was supplied in the Australian market for the Subaru BH Outback; specifications for other markets may vary. Furthermore, AustralianCar.Reviews has adopted the convention of referring to the post-2003 Subaru H6 engine as the EZ30R engine.

[su_table responsive=”yes”]

| Model | Engine | Trans. | Power | Torque | Years |

|---|---|---|---|---|---|

| Subaru BH Outback | 3.0-litre petrol F6 | 4sp auto | 154kW at 6000rpm | 282Nm at 4400rpm | 2000-03 |

[/su_table]

EZ30 block

The EZ30D engine had a die-cast aluminium cylinder block with 89.2 mm bores and an 80.0 mm stroke for a capacity of 2999 cc. Within the bores, the EZ30D engine had monoblock cast iron cylinder liners. Compared to the 2.5-litre EJ251 four-cylinder engine, the EZ30D was 20 mm longer and 40 kg heavier.

For the EZ30D engine, the water jackets were independent for the right and left halves of the block. The block halves were bolted together with 19 bolts (all located on the right bank of the engine), while the cylinder block and transmission cased were attached with 11 bolts.

The crankshaft for the EZ30D engine was supported by seven main bearings.

Intake

The EZ30D engine had straight tumble intake ports to promote air/fuel mixing and a variable intake system (VIS). The VIS used an induction control valve and operated as follows:

- At heavy loads below 3600 rpm, the valve remained closed to create separate intake runners, increasing intake air speed and creating a ram effect for greater power; and,

- At heavy loads and high engine speeds (i.e. above 3600 rpm), the valve would open to reduce airflow resistance – this created a ‘scavenging’ effect that allowed each cylinder to receive high-pressure waves of intake air as they rebounded off the opposite side of the manifold.

For the EZ30D engine, the intake manifold, chain cover and camshaft cover were made from cast aluminium.

Cylinder head and camshafts

The EZ30D engine had an aluminium cylinder head with chain-driven double overhead camshafts (DOHC) per cylinder bank. The camshafts were made from carbon steel pipes and had sintered metal lobes. During construction, the lobes were affixed to the steel pipes using a sintered metal paste; the camshafts were then baked until the paste hardened. For the EZ30D engine, the lobes of the camshafts were offset by 1 mm to rotate the camshaft bucket and shim to reduce wear.

The EZ30D engine had two timing chains – the left timing chain had 148 links and the right timing chain had 134 links. The timing chains were sprayed with oil from a jet located on the oil pump relief valve housing and did not require maintenance since oil pressure and spring tension maintained chain tension.

Valve timing

As per the table below, the EZ30D engine has intake duration of 240 degrees, exhaust duration of 232 degrees and valve overlap of 5 degrees.

[su_table responsive=”yes”]

| EZ30D valve timing | ||

|---|---|---|

| Intake | Open | 5° BTDC |

| Close | 55° ABDC | |

| Exhaust | Open | 52° BBDC |

| Close | 0° ATDC | |

[/su_table]

Injection and ignition

The EZ30D engine had sequential, multipoint fuel injection via ‘air assist’ fuel injectors; the injection and firing order were 1-6-3-2-5-4. Dual air/fuel sensors were used to monitor fuel mixture after combustion and continual adjustments were made to reduce exhaust gas emissions.

The EZ30D had a direct ignition system with an individual ignition coil for each cylinder (i.e. ‘coil-on-plug’), eliminating the need for a distributor and spark plug wires. Dual knock sensors enabled the ECU to adjust ignition timing in response to combustion noise feedback.

The EZ30D engine had a compression ratio of 10.7:1; 95 RON premium unleaded petrol was specified so that the maximum possible ignition angle could be utilised.

Exhaust

The EZ30D engine had one exhaust port per cylinder head and three catalytic converters: one in each of the left and right exhaust manifolds and another in the mixing chamber. The E-OBD system monitored the operation of the front catalytic converters.

The EZ30D engine was fitted with a dual stage exhaust system. At higher engine loads, i.e. when exhaust pressure reached around 2.2 psi, a mechanical valve in the rear muffler would open to bypass a section of the muffler and increase exhaust volume. By reducing exhaust back pressure, power was enhanced at higher speeds. The dual-stage exhaust, however, did not affect the volume of exhaust noise.